Where does diesel fit into the ‘Renewable Energy’ economy?

We all know energy is one of the highest operating costs for Australian miners.

Large haul trucks, heavy machinery, processing plants, conveyors to railway spanning hundreds of miles– a lot of power is needed to deliver ore from pit to port.

And this is only expected to rise in coming years as miners extract deeper, lower-quality ore that requires greater processing.

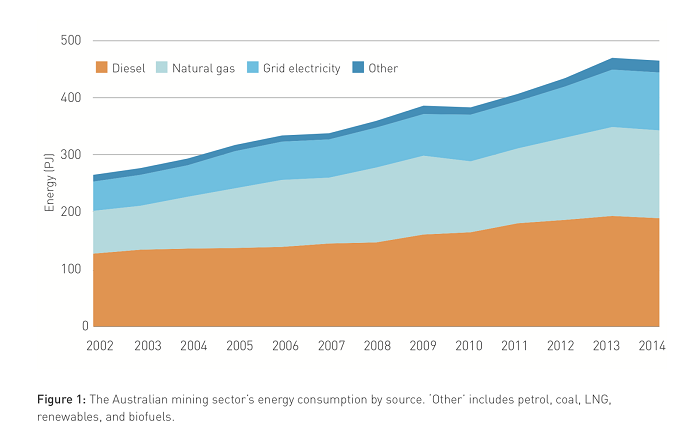

According to the Australian Renewable Energy Agency (ARENA), the sector currently accounts for about 10% of Australia’s total energy use (500 petajoules per year). Of this, diesel is the main contributor (41%) followed by natural gas (33%), and grid electricity (21%).

The Rise of Hybrid Systems

However, a ‘New Energy’ economy is emerging that is changing the way mining companies power their operations.

Solar farms, wind farms and batteries are making their way into sites. And for companies not already on the renewables wagon, we can only assume discussions are on the table.

In its 2017 white paper, Renewable Energy in the Australian Mining Sector, ARENA said diesel is historically the “favoured fuel source” along with natural gas, but the concept of an ‘all-electric mine’ integrating renewables, batteries and traditional energy was building momentum.

Australian mining energy consumption by source. Image: ARENA.

“Large-scale hybrid systems are gaining traction in the mining sector,” ARENA said. “Recently installed systems in Australia and Canada combine diesel with solar PV or wind, with capacities up to 47MW diesel/9.2MW wind and 19MW diesel/10MW solar PV.”

With renewable capacities anticipated to advance further, many are left with the question: where does diesel fit into the future energy mix?

Miners Making Moves

First, let’s take a look at the renewable systems already deployed across mines around the globe.

Sandfire Resources

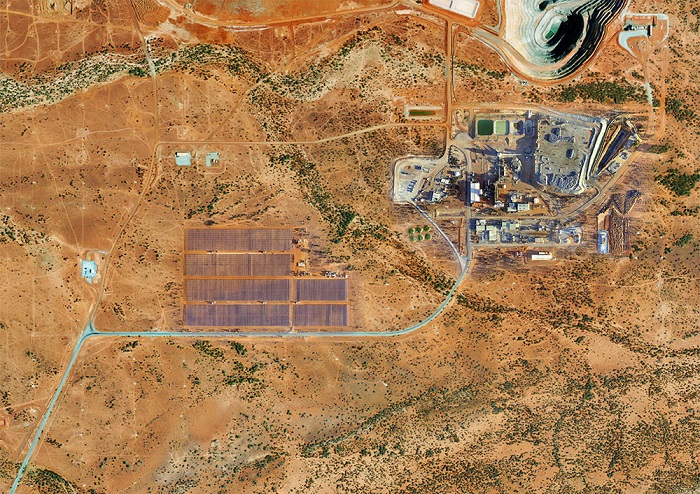

Diversified miner Sandfire Resources was one of the first Australian miners to build an off-grid renewable application.

In 2016, it commissioned a 10.6 MW solar PV installation at its brownfield Degrussa copper-gold mine in WA, which is connected to a new 6MW lithium-ion battery storage facility and its existing 19MW diesel-fired power station.

The $41 million facility, partly funded by ARENA, is owned by Neoen, operated by EPC contractor juwi Renewable Energy, and provides about 15-20% of the mine’s energy needs (21GWh per annum). This has led to a 5ML reduction in diesel consumption a year.

The Degrussa solar array in WA. Image: Sandfire Resources.

Antofagasta & Barrick Gold

In July 2018, Antofagasta and Barrick Gold announced their joint venture copper project Zaldívar would utilise 100% renewable energy by 2020, which will reduce its greenhouse gas emissions by 350,000 tonnes per year for 10 years. The mine will use a combination of wind, solar and hydro energy.

Rio Tinto

Between 2008 and 2017, mining giant Rio Tinto has reduced its greenhouse gas (GHG) emissions intensity by 27%, according to Deloitte. Today, about 75% of the company’s energy comes from hydroelectric, nuclear, and renewable power sources. In northern QLD, Rio’s Weipa bauxite operation includes a 6.7MW solar PV farm, which reduces 600,000 litres of diesel consumption a year.

Gold Fields

Gold-miner Gold Fields will also soon install a new mobile and modular energy storage system at its Granny Smith project in WA. The facility is one of the world’s largest renewable energy microgrids and will include 20,000 solar panels and a 2MW/1MWh battery system. The solar-plus-battery system is projected to reduce fuel consumption by 10-13%.

Renewable Energy Challenges

While renewable energy sources have a host of benefits for miners, there are still many limitations. Reliability has been a key issue raised by many.

ARENA also flagged operating lease versus capital lease as a matter, technical integration particularly among offtakers, commercial integration, as well as a mismatch between contract duration and asset life.

For instance, solar PV assets typically have an operating life of 30 years, and some sites only have a small mine life of five to 10 years, and are so remote that to move infrastructure at the end of mining is not economically feasible.

Although, there were already solutions being implemented to de-risk renewables in mining, including SunSHIFT, a plug and play mobile solar module developed by Laing O-Rourke in partnership with SunPower, ABB and ARENA. The solar PV system comes in an array of sizes and can be bought, rented or available via power purchase agreements. Interesting stuff!

The ‘plug and play’ SunShift solar system. Image: SunShift.

Diesel: A Strong Future

There’s no denying with all of this change, something’s got to give.

And while diesel may experience a reduction in demand in the mid-term, we are of the firm view it will remain a key energy source for mines for years to come, particularly when it comes to powering heavy machinery and haul trucks.

Diesel is also a proven reliable source. It’s trucked in, safely stored in bulk fuel storage tanks (like ours) and can power up trucks even when the sun isn’t shining or the wind isn’t blowing.

This topic was discussed at length at the April Bauma conference in Munich, which put a spotlight on all the latest industry technologies and innovations.

Diesel Technology Forum executive director Allen Schaeffer said that diesel engines are the technology of choice for fuelling the largest off-road machines and equipment types globally, for many reasons including the energy density of diesel fuel.

“The credentials for the future are innovative, automated, efficient, connected and clean, which ensures that advanced diesel technology will continue to play a dominant role in these vital sectors of the global economy,” Mr Schaeffer said.

“Equipment on display in Munich by industry innovators and leaders including AGCO, Bosch, Caterpillar, CNH Industrial, Cummins, John Deere, MTU, Volvo Penta and Yanmar demonstrate diesel’s continued capability to meet the commercial demands of customers along with improved environmental performance that will keep clean diesel in the driver’s seat of the global economy for decades to come.

“It’s all about doing more work with less fuel, not only on a machine basis but also through integrated and connected site ecosystem.

Engine and equipment manufacturers are innovating to achieve increased productivity and fuel-saving for their customers, including for example hybrid and energy storage systems, where smaller diesel engines serve as electrical generators to lessen the load and deliver fuel savings and emission reductions.”

In short, diesel will remain the lifeblood of mining operations for decades to come.

Over to you: Where do you see renewables and diesel in mining in 10, 20 years down the track?

No comment yet, add your voice below!