A Best Practice Guide to Purchasing Fuel for Farmers

The purchasing process is central to efficient use of diesel and other liquid fuels.

Factors influencing liquid-fuel-purchasing decisions include storage life, potential fuel losses, and the legislative and financial implications of large-scale on-site storage. Fresh fuel is more energy-efficient than aged fuel, and planning the delivery of fuel around peak demand is key to effective fuel management. There are a number of buying strategies that can help you to negotiate the best price, avoid wastage and maximise return on fuel investment.

Introduction

Diesel and other liquid fuels account for up to 90 per cent of energy use in the NSW cropping and extensive livestock sectors (Energetics, 2013).

While farmers typically use large qualities of fuel – six-figure annual fuel bills are common – there are limits on their ability to purchase in bulk and gain the fuel price discounts achievable in other sectors of Australian industry.

This paper considers the key drivers of liquid fuel prices, considerations for storing purchased fuel to avoid losses and reduce cost, and the potential impacts of old or out-of-season fuel on engine efficiency.

Price fluctuations and their drivers

The price of petroleum products in Australia is affected principally by the following factors

- the crude oil spot market(s) and supply and demand factors such as world GDP growth projections and geopolitical supply factors

- the strength or weakness of the Australian dollar, particularly in comparison to the US dollar (as oil is bought and sold in US dollars), and

- federal government excise and taxes including the results of the parity pricing system. Farmers receive a 38.143 cent fuel tax credit. From 1 July 2012, credit was reduced with an amount equal to the prevailing price on carbon (Australian Taxation Office, 2013).

Australia’s regional market for petroleum products is the AsiaPacific market. The diesel price in our regional market is driven by supply and demand, not production costs. Australian demand growth for diesel has been strong, particularly as a result of the mining and commodity boom of recent years. This has contributed to the increase in the regional (Asia-Pacific) demand for diesel and as a result, diesel prices have risen in the region, including Australia.

Australian wholesale prices for petrol and diesel (including spot Terminal Gate Prices) are closely linked to the Singapore prices of petrol and diesel – not to crude oil prices. Australian fuel wholesalers use a pricing methodology known as import parity pricing which is based on what it would cost to import fuel into Australia.

The Australian Institute of Petroleum (AIP) publishes weekly reports on wholesale and retail pump prices for diesel and other fuels.

Around 25 percent of the diesel used in Australia is sold through retail outlets, with the other 75 percent sold in bulk to commercial/industrial customers, such as mining and transport companies, on long-term contract. Therefore, retail diesel prices are not subject to aggressive discounting between fuel retailers, as petrol more commonly is. In more remote and regional areas of Australia, diesel retail prices are set primarily by independent owner/operators. Higher prices reflect lower fuel volumes and sales along with increased freight and distribution costs. Limits to on-farm fuel storage Safety and compliance Economically, the cost of purchasing a compliant fuel storage tank plus required bunding and safety controls could be prohibitive in making large-scale fuel storage a viable, cost effective option.

Quick Tips

- Don’t try to ‘pick the market’.

Buying ‘cheap’ is generally a risky strategy.

- ‘Fresh’ fuel is more energy-efficient.

Limit the amount of fuel you purchase to no more than a month of the supply required to support operations.

- Keep good fuel records.

Can help for planning purchases well ahead of time.

- Synchronise your purchasing cycle

Plan ahead for expected winter/summer fuel changes (for instance, re-stock in May for your winter fuel requirements).

- Use a supplier that guarantees fuel quality

Use a supplier that provides detailed delivery data in a format that facilitates your own record keeping and fuel management system.

- Maintain infrastructure.

Ensure that tanks are well sealed to keep out dust and water, and install filtration devices.

Limits to on-farm fuel storage

Safety and compliance

Economically, the cost of purchasing a compliant fuel storage tank plus required bunding and safety controls could be prohibitive in making large-scale fuel storage a viable, cost-effective option.

What is a Bund?

“A bund is a structure designed to prevent inundation and breaches.”

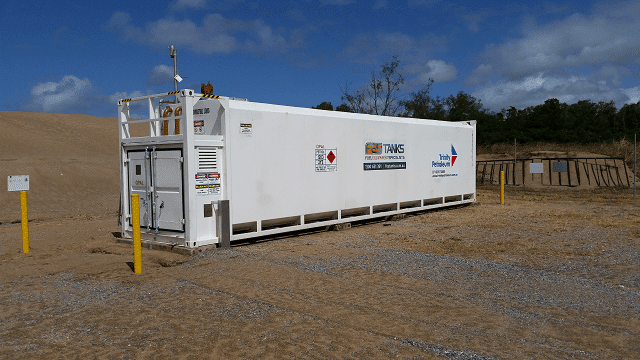

Externally self-bunded fuel tank with crash-protective posts

Internal ISO containerised self-bunded fuel tank with crash-protective posts

Each state in Australia has legislation in the form of Acts and Regulations for Workplace Health & Safety (WH&S) and for protection of the environment. Owners of above-ground tanks and fuel suppliers have obligations under their respective state legislations, breaches of which may carry heavy penalties.

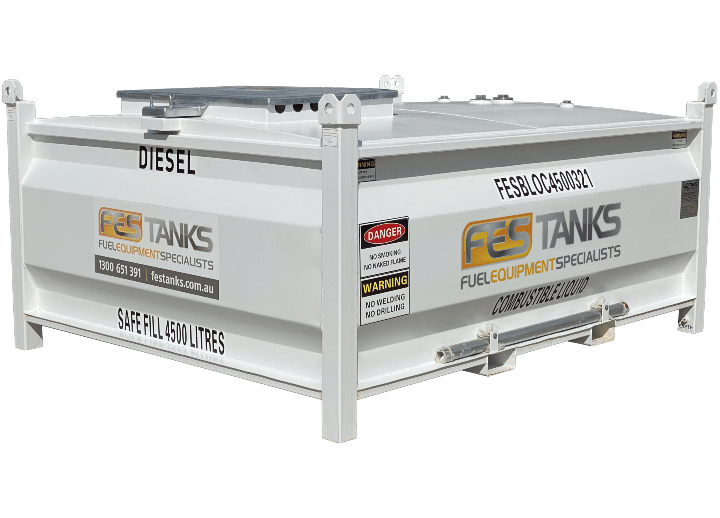

Smaller bunded tank options also exist and are adaptable to on-site requirements. Environmental regulations vary dependent on local authorities but we would recommend tanks over 4000 litres need to be protected by some form of bunding in case of leakage or rupture.

4,500 litre internally bunded fuel storage tank.

Storage life of fuel

Fuels deteriorate and are formulated to suit specific seasonal conditions. Using old or out-of-season fuel will reduce engine efficiency and increase services costs. A sensible limit on the size of a single bulk delivery is therefore the quantity of the fuel that a farm can use while that fuel remains fresh.

Under normal storage conditions, diesel fuel can be expected to stay in a useable condition for 12 months or longer at an ambient temperature of 20 °C; six to 12 months at an ambient temperature higher than 30 °C (British Petroleum, 2005).

As diesel gets older, fine sediment and gum forms in the fuel, brought about by the reaction of diesel components with oxygen from the air. The fine sediment and gum will block fuel filters, leading to fuel starvation and to the engine stopping.

Frequent filter changes are then required to keep the engine going. The gums and sediments do not burn in engines very well and can lead to carbon and soot deposits on injectors and other combustion surfaces, and to a corresponding decrease in combustion efficiency.

Other costs to consider are the maintenance cost of tanks, and the capital tied up in the inventory of fuel being stored.

Fuel quality issues

Cleanliness of diesel is very important and can reduce engine efficiency and engine life significantly. These problems compound if large-scale storage is considered. Dust and water are the main offenders in fuel cleanliness, but there is a range of technology available for continuous tank filtration, filtration at delivery point and on-vehicle filtration. Some experiential data has shown improvements in fuel economy by up to four percent, subject to initial fuel contamination (LSM Technologies, 2013) (Parsons Australia, 2012).

The difference between summer and winter diesel is the ‘Cloud Point’ property. All diesel fuels contain wax, which is usually a liquid solution in the fuel. At low temperatures, the wax begins to solidify and crystals form in the diesel. As the temperature drops, these crystals grow and can block filters, starving engines of fuel. The Cloud Point is the temperature at which the wax crystals first appear. At this stage they are too small to block diesel engine filters.

Generally, summer and winter additives won’t have a large impact on engine efficiency. The specification for diesel varies by month so that the fuel available is appropriate for the expected seasonal weather. There is a two-month lead time on the distribution of the fuel, so that any diesel purchased in May will be winter grade, suitable for the cold period from the start of May until the end of July. To avoid winter waxing problems, plan to change over all your diesel fuel by May at the latest. It is important that you don’t keep summer fuel for winter use. Suppliers such as BP provide information on how to identify and rectify this problem(British Petroleum, 2005).

Buying strategies

The price of diesel fluctuates due to an array of factors, as discussed. However, buying diesel in bulk (greater than one or two months’ supply, for example, in large-volume users) is rarely a viable strategy for farmers due to the storage life of diesel, the cost of storage and the stringent regulatory requirements for storing flammable and combustible fuels on farms. Security of supply will also be a concern for larger operations as the diesel supply chain is structured for supply at regular intervals. Such a strategy could result in a shortfall in farm fuel supply at a critical time.

Individual farms are unlikely to consume sufficient quantities of fuel to attract significant bulk fuel discounts. In pursuit of logistical savings, distributors may in future change patterns of delivery to small consumers. Establishing or becoming part of buyer groups or cooperatives may be an alternative if this offers sufficient volume to be attractive to suppliers.

A feasibility study (Co-operative Development Services, ltd., 2001) into rural fuel cooperatives in Victoria has found that the most efficient and least risky option for supply and delivery of fuel to primary producers and other bulk fuel users is for a cooperative to act as a fuel broker. This study suggested that the risks in price volatility must be transferred by cooperatives to the supplier.

Extracted from the NSW Farmers Association ‘Farm Energy Innovation Program’. [click here]

Conclusion

You more than anyone will know your buying patterns in relation to the daily operations of the farm. What is less known is the external forces that dictate the reliability of your supply chain.

Always maintain frequent communications with suppliers so as to understand the market place and to be ahead of any potential supply and pricing issues.